Nano telescope

Implant System

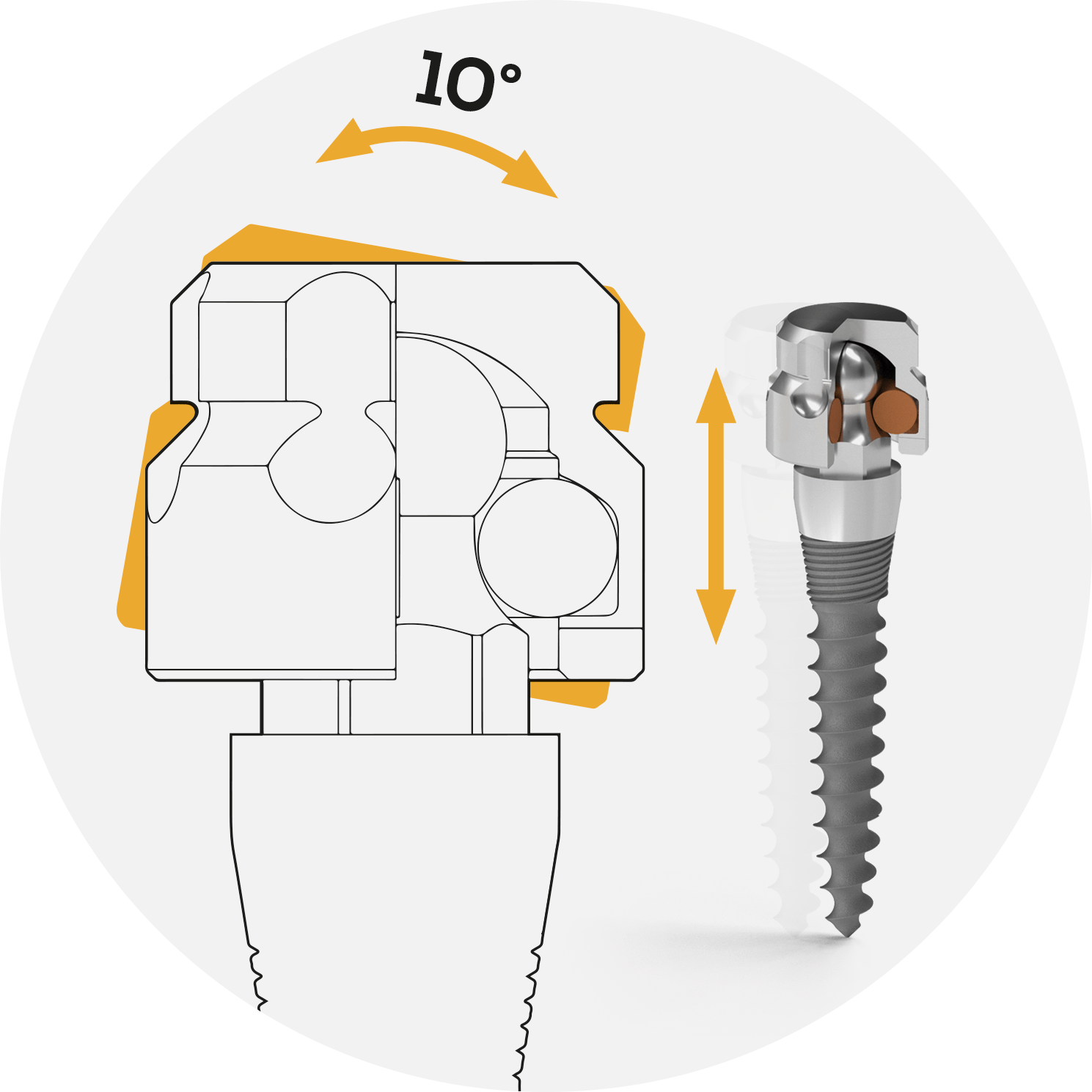

Nano telescope – The flexible tooth fixation

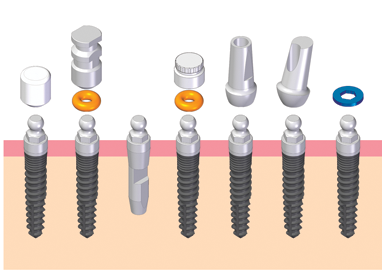

The Nano Telescope Implant System can be used in the case of harder than average and thin bone structures, for removable toothworks.

Distinctive constructional and applicational characteristics:

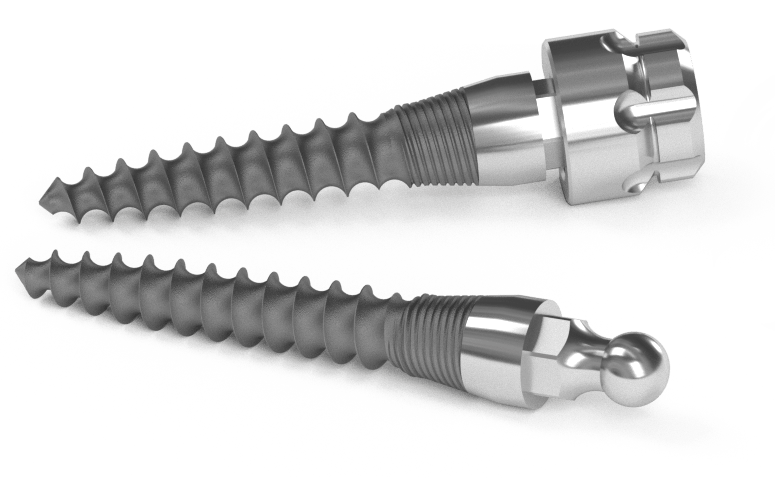

Minimal invasive intervention • Flexible toothwork connection • In the case of the harder mandibula bone structures the MD implant screws are recommended to use and in the case of the lighter maxilla bone structures the MX implant screws are recommended to use • High primer stability- immediate „loadness”, with a torque above 35 Ncm screwed into the jaw bone • Screw selectional possibility adjusted to the height of the sulcus • Conical, cycloid cord thread • Self-compressional, self-tapping and self-closing conical thread form •Self-cutting thread edges, with anti-rotation function

The characteristics of the Nano Telescope Implant System:

• Screw selectional possibility adjusted to the height of the sulcus. Polished surface according to the 2 to 3 mm or unique size sulcus. • Conical cord thread on the upper neck part of the screw which exceptionally resists dynamic force reduction, gradually deepening and sharpening

• The self-compressional, self-tapping and self-closing conical thread form gradually deepens in the middle and lower parts of the implant screw. • The cycloid thread form is adjusted to the spongy bone structure, the thin threaded edge is more suitable for the harder cortical bone structure. • Self-cutting thread edges, with anti-rotation function.

Applied raw materials

BIONIKA demonstrates the best qualities of Grade 4 titanium used in implant manufacturing for dental implantology according to the ISO 5832-2 ASTM F67 standard.

Due to its adequate purity the biocompatibility is exceptionally good as well as it is provided with exceptional solidity. Initially, we and other implant manufacturers preferred the higher purity titanium but due to solidity reasons nowadays almost every implant is made of Grade 4 or other alloyed titanium in the world.

In all cases of implant abutments, alloyed, high strength Grade 5 titanium is applied according to the ISO 5832-4 ASTM F136 standard. The quality of the products is guaranteed by design, manufacturing and quality management according to the harmonized European Union laws. The BIONIKA Medline Orvostechinkai Kft. is operated according to the EN ISO 9001 and the EN ISO 13485 quality management system. Our products are provided with CE marks, which is certified by the TÜV Rheinland.

The titanium applied according to the standard is provided with exceptional biocompatibility, it is almost risk-free.