Comparative analysis of surface characteristics of implants

The researchers of the Department of Dentistry at the University of Debrecen and Health Sciences, Department of Prosthodontics, Department of Solid State Physics at the Debrecen University and the Institute of Biophysics and Cell Biology at the University of Debrecen: DR. KATONA BERNADETT, DR. DARÓCZI LAJOS, DR. JENEI ATTILA, DR. JÓZSEF BAKÓ, DR. HEGEDŰS CSABA has launched a serious comparative study on the surface design of the most well-known domestic and foreign implants types in Hungary. This project also involved BIONIKA Medline Orvostechnikai Kft. By choosing one of our successful systems, the CorticaL branded implant, I asked Professor Hegedűs Csaba, Dean of the University of Debrecen, to be able to participate in this project. I would like to thank you for this opportunity.

The most important aim of this study was to explain the fact that as a consequence of our special surface treatment technique, based on the experience of the past 25 years:

- It seems that our implants are extremely well integrated in contrast to the implants of our competitors. We often get feedback from our implantologist partners using our products.

- We also had an important goal not only to find differences but also about the same properties as compared with most commonly occurring implants distributed in Hungary.

The researchers reported their findings in the Fogorvosi Szemle journal. The full independent, most important test results and the extract of the article are published in the following quotation: “The material composition and surface roughness of dental titanium implants are important in the osseointegration process and implants need to meet additional requirements such as biocompatibility, strength, corrosion stability and industrial producibility. In the course of the work of the authors, the surface morphology and material properties of seven known implants (Denti Bone Level, Denti Zirconium C, Bionika CorticaL, Straumann SLA, Straumann SLA Active, Dentsply Ankylos, Biotech Kontact implants) were investigated by a scanning electron microscope (Hitachi S-4300, Japan). During the sand blasting, the surfaces of the implant were roughened with high speed and hard particles. The physico-chemical properties of the material used are important because they can greatly influence the properties of the surface created, but they should not impede the osseointegration processes of the implant. By the technique of acid etching, it is immersed into a mixture of strong acids, , micro cavity titanium surface is obtained. The double acid etching may facilitate the adhesion of bone-forming cells and fibrin filaments to help bone formation on the implant surface. In their work, it was shown that – although the two most common surface treatment techniques described above (sandblasting, acid etching) have been applied to the types of implants examined, different surface morphological features are observed. Prior to performing electron microscopic investigations, the examined objects were embedded in cold and / or warm embedding materials, depending on how much the implant was provided with internal dispersion. Due to the surface characteristics, Denti Bone Level, Straumann SLA and Bionika CorticaL implants were vacuum impregnated in high pressure EpoFix resin in Cito Vac impregnating equipment…

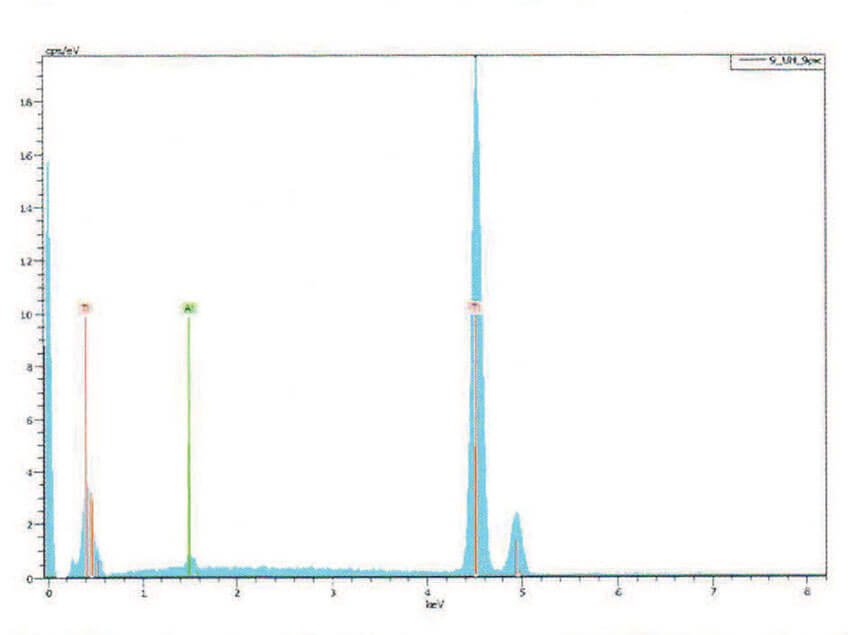

4d. Illustration 2: Energy-dispersive X-ray Spectrometric Elemental Analysis of Bionika CorticaL Implant

Results

TheBionika CorticaL implant has a high pitched, high threaded saw toothed screw profile. On the 3b illustration the surface is formed through acidification and electrochemical purification processes can be found. Surface electron microscopic images contain a number of black spots, which are not visible in the cross-sectional view (Illustration 3a). In the elemental analysis Al was present beside the Ti alloy (Illustration 3d).”

Reflecting on the findings of the results, I would mention that the design of the CorticaL implant thread is a completely unique “saw-toothed” thread that is called an epoxy thread due to its characteristic profile. With this design, the strength and surface size of the thin parts of the implant continued to improve. Basically, we do not prefer the sharp radial solutions instead we prefer the solutions which are more suitable for the biological organization. As a result of this property, the spongy bone structure is better able to bear the dynamic forces.

4b. Illustration of EM Straumann SLA implant

Researchers also made objective statements about the surface structure. As an explanation, we need to state that our experimental experiences have been able to achieve depths of roughening and acid etching that appear on the illuminated surface in darker craters of several microns of magnitude. On the 3b. illustration it can be seen that the roughness of the surface consists of much larger craters than the Straumann SLA in illustration 4b.

This greatly improves osseointegration. Surface treatment findings are also valid, and indeed the same technology is used for the Straumann SLA surface design technology. On the 3d illustration it can be seen that the energy-dispersive X-ray spectrometric analysis of the energy analysis is similar to the results made in the Bay Zoltán Applied Research Public Nonprofit Ltd. in the Logistics and Production Engineering Institute. Since Cortical is a wide-spectrum dental implant system, therefore, it is necessary to use a high-strength titanium alloy implant material according to the ISO 5832-3 standard containing aluminium due to solidity deliberations. Without deteriorating the biocompatibility, a significant increase in strength can be achieved, which is particularly justified in the manufacture of implants with a diameter of 3 mm or less. As a conclusion, we can sum up , that the researchers’ results confirm our previous investigations and our 25-year experience well. The formation of the surface structure of the implants begins to unit. Nearly the same technology is used for in the most renowned research and development companies, including BIONIKA. The choice of the applied implant raw materials is increasingly shifting towards biocompatible materials with higher strength.

Source: FOGORVOSI SZEMLE, year 106 No. 4 2013. 135-143

Hajdú József

Msc Applied Mechanic Engineer

Health Manager Economist

Article information

- Author | Hajdú József

- Date | 2014.01.01

- URL | www.bionika.hu